Over the past four years of writing the Kristian Electric blog, we have worked hard to share exciting updates from across our company – expert interviews, crane manufacturing and installation jobs, technological advancements, and new offerings from suppliers like Miller and Gorbel. But as we dive deeper into 2019, we want to turn the spotlight around and give thanks to the wide range of customers who trust Kristian to keep their equipment running. That’s why we are starting a new series on the Kristian Electric Blog – Customer Spotlights. We will take you along as we visit some of our coolest customers and talk about what they do, what equipment they love, and how they provide services for Albertans.

Inline Fabrication

Calgary, AB

We’ve gotten to know Inline Fabrication pretty well over the years as they always choose KEL to repair their welding and plasma cutting equipment when it breaks down.

Inline Fabrication is nestled in Calgary’s Ogden Industrial, located on 17 Street SE. They are a fabrication and machine shop mainly serving customers across Alberta’s oil and gas industry. We were lucky enough to get a tour through the shop by Cody Johnson, Lead Hand, and learn a little about Inline and what they do.

Q: How long have you been in business?

About 15 years. We have been at our current location in Ogden Industrial since I started working here.

Q: How did you get started in the fabrication business?

I knew Mike Nghi, the owner, through family ties. I was welding out in Airdrie before I started full-time at Inline about seven years ago. Since then, everything I have learned has been on the job training. I do a little bit of everything – welding, fabrication, purchasing, billing, etc.

Q: How many employees do you have?

About six full-time staff.

Q: What products do you mainly fabricate for your customers?

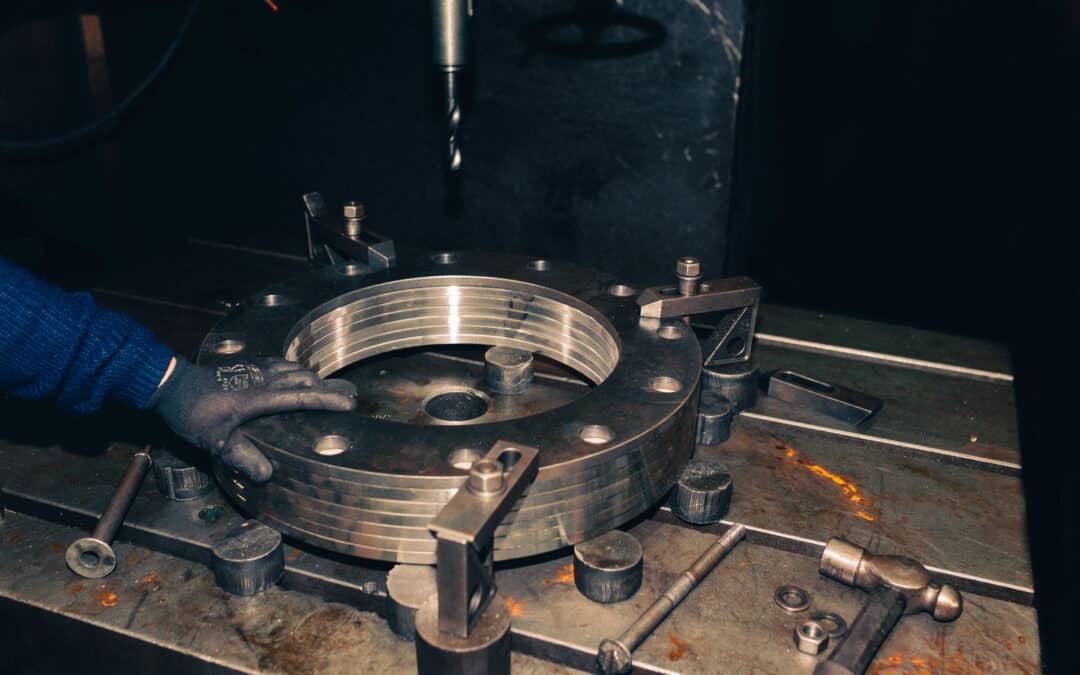

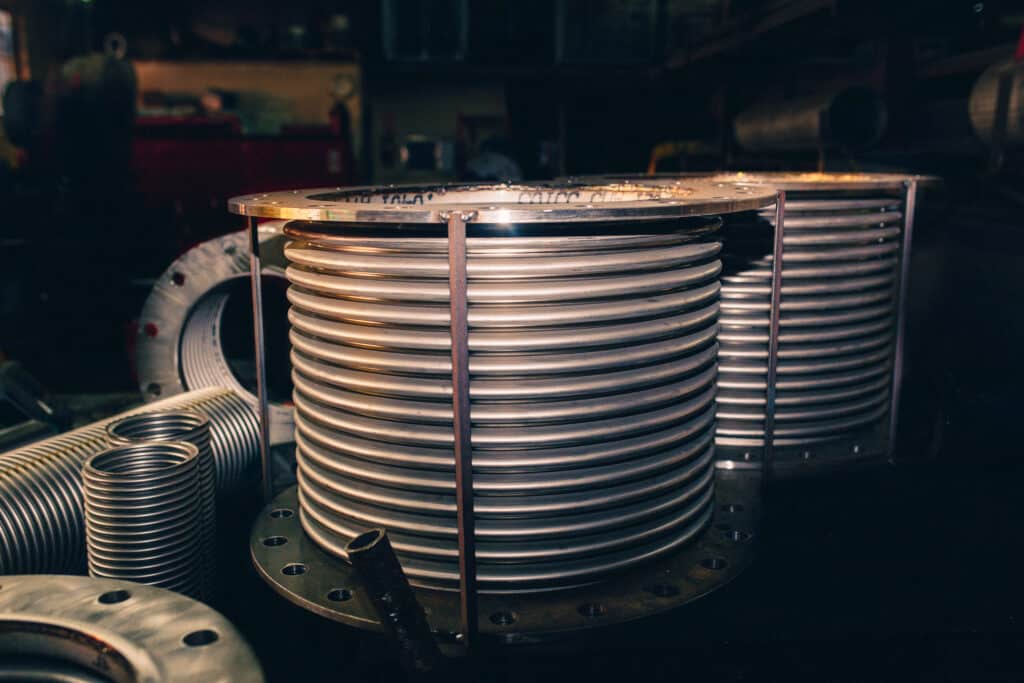

We fabricate all kinds of products for the oilfield, ranging from plate flanges to cone strainers, but we definitely specialize in expansion joints.

Metal expansion joints are used for many applications in the energy industry and are used to compensate for exhaust heat, movement and vibration as they are flexible connections to take stress off the pipeline.

Q: Can you describe your customers? Why do they choose Inline over your competitors? What do you believe sets Inline Fabrication apart?

Our customers are typically all larger companies in the oil and gas industry: suppliers of oil and gas production equipment and gas compression equipment. We fabricate for most of our customers in the field, so we are constantly shipping out completed work across Alberta and British Columbia.

As for our strengths, I would say number one is our speed. We have an incredibly fast turnaround time, which we have seen time and again is very important to our customers. Other companies may quote two weeks for a job that I can start, complete and ship out next day. Having an excellent turnaround time combined with competitive pricing maintains our strong and loyal customer base.

Q: What does your standard process look like?

First, the paperwork comes into the shop and we figure out what raw materials we need for what we have to build/fabricate. All product we make from scratch. We order raw steel and make what we need to fulfill the customer’s request, then we ship the completed product to the customer in the field.

Q: What kind of equipment do you use? What do you like about this equipment?

We use MIG welders from Lincoln – right now we are using a Lincoln CV 300 and a Lincoln Invertec STT II. When we need to do TIG and Arc welding, we use Miller machines. (not pictured)

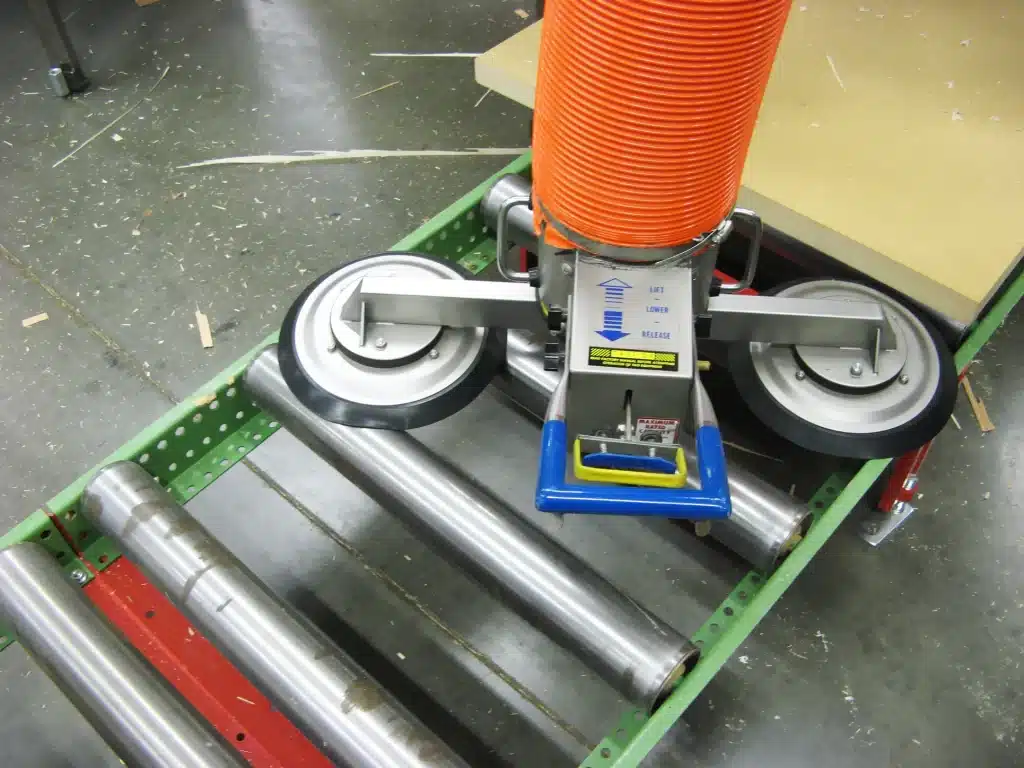

Our Plasma Cutters are all Hypertherm – right now we are using Hypertherm Powermax 1000 and Powermax 45 plasma cutters (hand torch) and a Hypertherm Powermax 1650 with our CNC Plasma Table. We swear by Hypertherm Plasma Cutters because they never let us down in quality.

Q: What do you see in the future for your business?

I want to see us growing and expanding on what we do — have our products reach new markets and be able to branch out and acquire new customers.

Phone: +1 (403) 720-8000

Fax: +1 (403) 720-8550

Email: inlinefab@gmail.com

Address: 4119 17 St SE, Calgary, AB T2G 3W5

Website: inlinefabrication.ca

If you or your company is interested in being profiled, please reach out to profiles@kristian.ca