Hang in the Balance – A New Intuitive Hoist from Demag

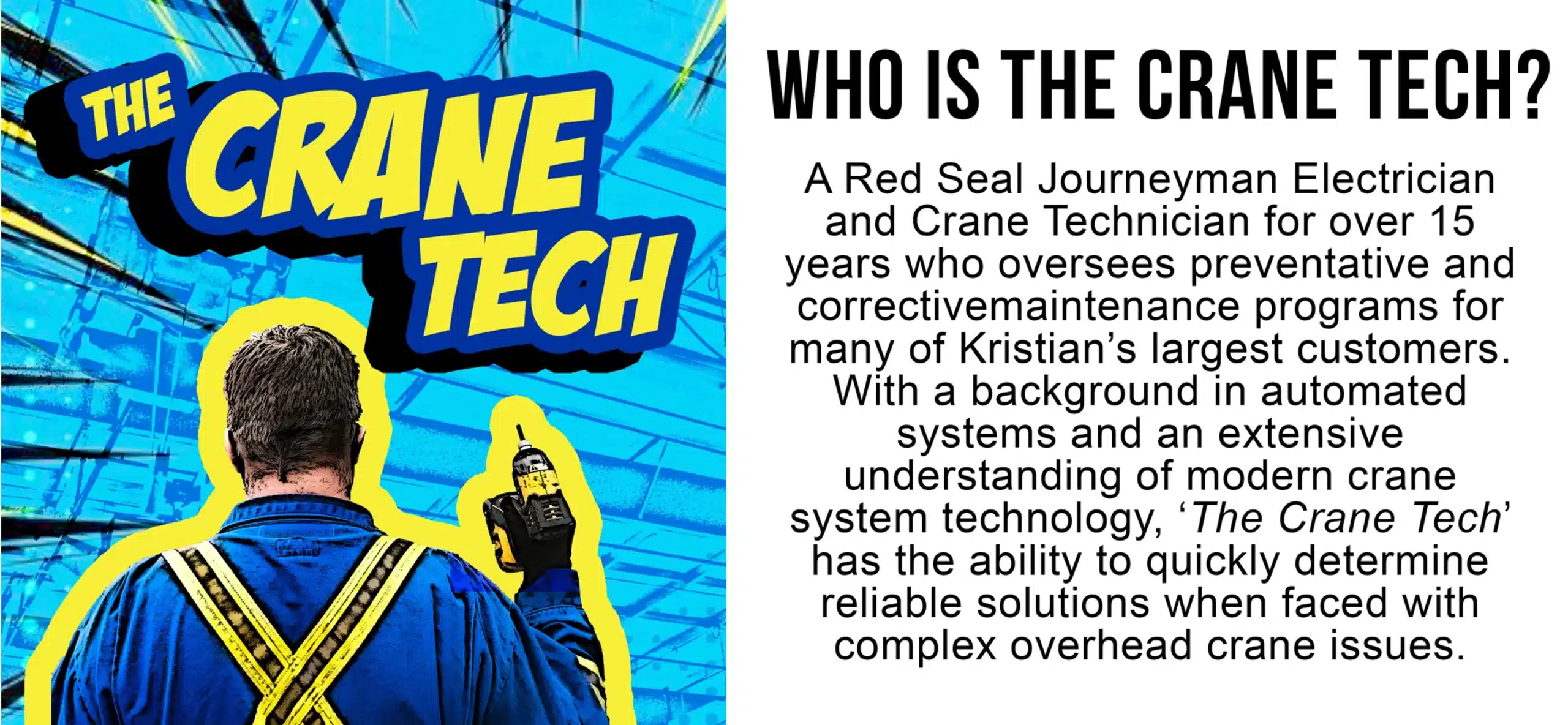

This content reflects a period in Kristian Electric’s history when we were an authorized Demag dealer and warranty depot. Although that partnership ended in October 2025, our expertise didn’t — we continue to service Demag cranes, source parts, and support customers across Canada.

Demag is a world leader in material handling innovation and design and there has been no exception to this rule with the introduction of their latest design, the DCBS chain hoist. Designed with the same reliable versatility and quality as the rest of the DC chain hoist line, the DCBS also includes an innovative balance function, making intuitive lifting easier than ever.

The brilliance behind the DCBS chain hoist lies in the state-of-the-art hand grip, known officially as the D-Grip Servo. This servo is equipped with two different sensors installed to make lifting simple. The pressure sensor is used to control the direction and speed whilst in Manual or Grip Mode, and a load sensor that is used for balancer control and continuously monitors the attached load.

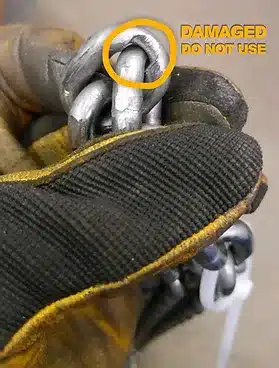

e hoist also comes programmed with a change detection threshold that will activated and cause the brakes to apply if there are changes in the loads balance. For example, if a load is set down on an angle or on an edge of a platform, the brakes will apply and not allow the load to tip and fall.

The DCBS provides 4 selectable modes available to the operator to precisely position loads.

Grip Control Mode

The user can easily control the load positioning by manipulating the ergonomic D-Grip Servo. The photocell installed on the back of the handle-grip activates this mode when covered.

Load Positioning Mode

This allows to operator to grasp, guide and direct the load directly with ease. Since the device is controlled by the operator’s natural movement, the pace is as slow or as fast as the job requires.

Assembly Mode

In this mode the system can only be controlled by the load itself. If the operator covers the photocell on the D-Grip Servo, the system automatically returns to manual force mode, with higher lifting speeds. This also applies if the load comes into contact with an obstacle. With oscillation and uncontrolled load movements supressed, the level of safety and precision increases markedly.

Load Pick-Up Mode

Though not installed upon purchase, this mode can be programmed using the cable connector and software that comes with the unit. This allows the user to set up the specific parameters for their unique lifting situation. Once installed this mode allows attachments to be lifted and pre-tensioned, the load can be removed without dropping or sudden upward pull and the balancer will only lift until a pre-set force is reached.

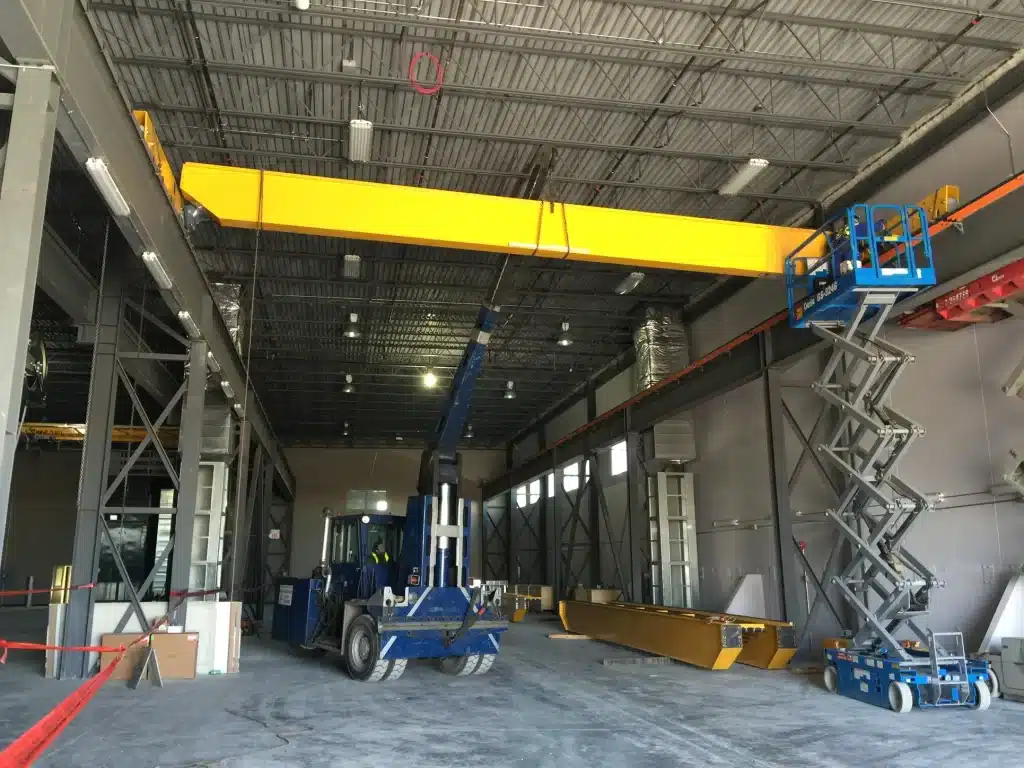

DCBS units are available in two sizes with load capacities up to 160 kg. They are compatible with the Demag KBK light crane systems and can easily travel on single-girder suspension cranes, suspension monorail systems or on slewing jib cranes.