In today’s industrial workplace, heavy-duty equipment can be quite common place. However the constant exposure to this dangerous machinery can cause a sense of apathy and carelessness by some individuals, which is a detriment to the safety of that worker and their co-workers.

From mines to shipping ports, meat packing plants to auto body shops, overhead cranes can be found in a huge array of work environments. Each of these environments come with their own safety concerns but the safe operation of an overhead crane should be of high priority.

Occupational Health & Safety (OHS) requires that all overhead crane operators need to be trained by a certified instructor in the field and pass a written or oral examination as well as a practical operating examination. All trainees need to be deemed physically and mentally capable. Including normal depth perception, field of vision, reaction time, manual dexterity and coordination. While ruling out any tendencies of dizziness or similar physical conditions.

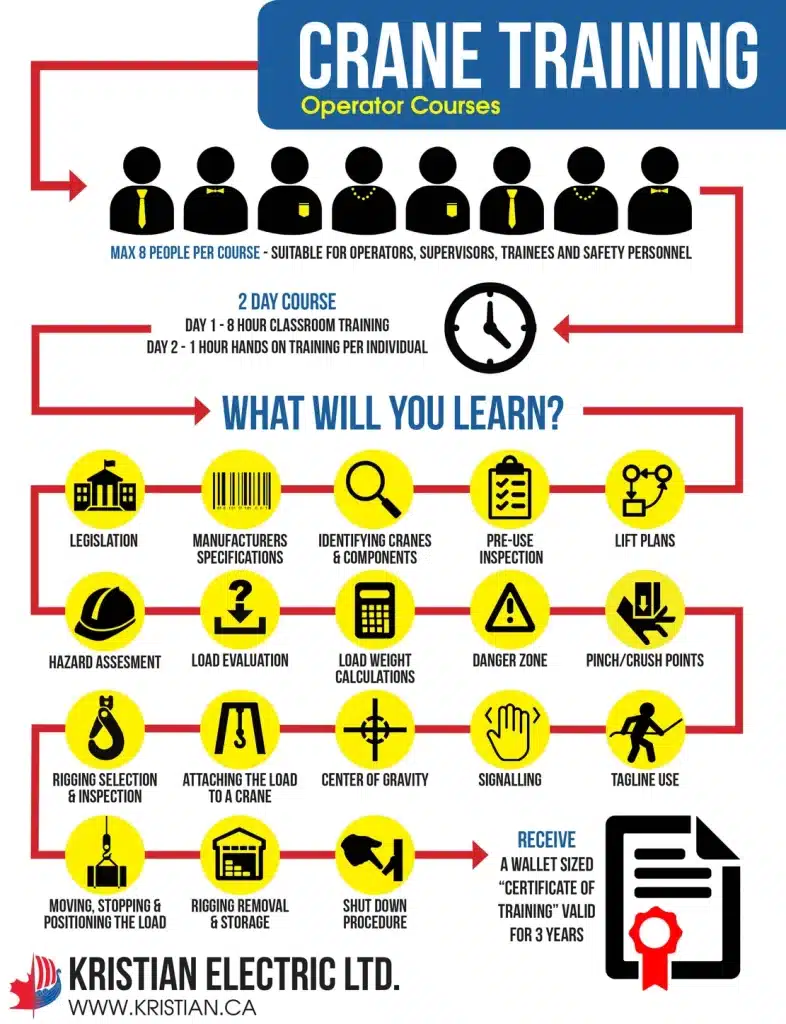

Courses are typically a two day program. With the first day being dedicated to in-classroom instruction, including presentations, class discussion & exercises, video presentations and a practical exam. While the second day provides a one-on-one instruction and evaluation with each trainee individually. This portion of the course is typically carried out at the trainee’s personal workplace on the equipment they would be using.

Course topics include:

-

-

Legislation

-

Manufacturer’s Specifications

-

Identifying cranes and their components

-

Pre-use inspections

-

Lift plan

-

Hazard assessment

-

Load evaluation

-

Load weight calculation

-

Danger zone

-

Pinch points/crush points

-

Rigging selection and inspection

-

Attaching the load to the crane

-

Center of gravity

-

Signaling

-

Tagline use

-

Moving the load safely

-

Stopping the load safely

-

Positioning the load

-

Removal and proper storage of rigging

-

Shut down procedure

-

Each trainee is expected to score a minimum or 70% on both the theory and practical examinations.

Upon completion each individual with passing grades for both examinations will receive a “Certificate of Training” which is valid for the next 3 years.

Kristian Electric offers two safety courses for your consideration;

Overhead Crane Course: Suitable for all overhead crane operators, trainees, supervisors and safety personnel.

Hoist Operator Course: Suitable for operators of monorail hoists, jib hoists, Gorbel systems etc.

Kristian Electric’s safety training courses follow OH&S Safety bulletin IS009 “guidelines for Safety Training of Overhead Crane Operators and Supervisors”.