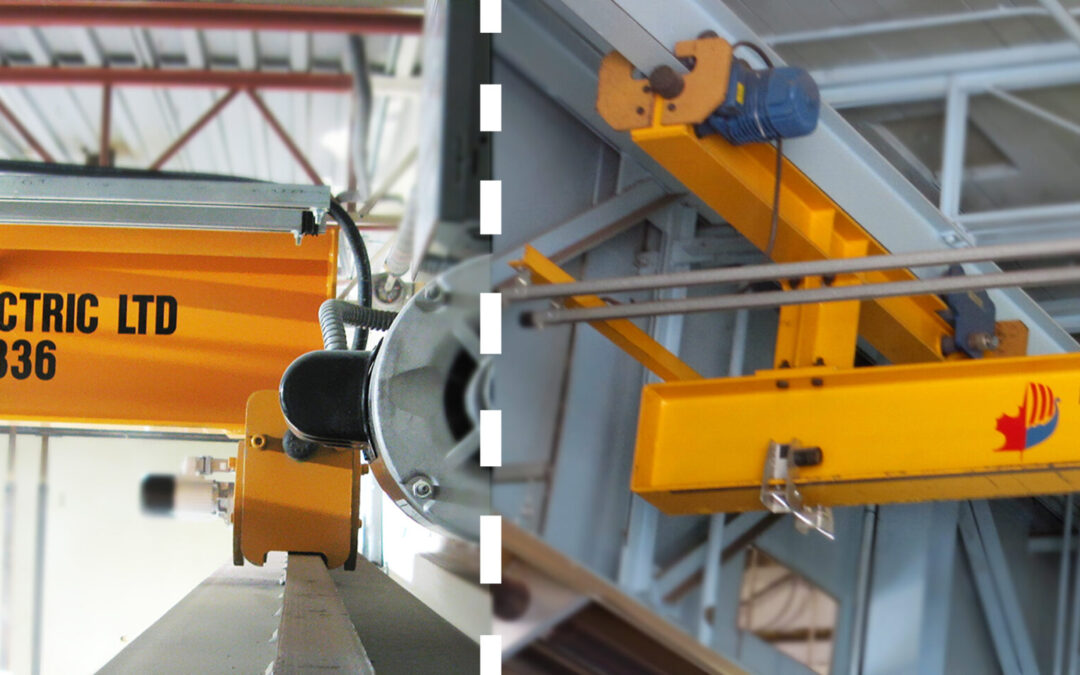

Top running cranes are affixed to runways that are constructed along a system of columns, corbels or related supporting structures. By ensuring that the top-running crane is sustained by a reinforced support system, this enables for the competent and safe lifting of much heavier loads by not putting extra strain on the framework of the actual building.

With the bridge of the crane running above the runway system, this also allows the user a much higher lift. A higher lift is a favourable option for facilities that require an adequate amount of headroom when lifting large loads that need to be lifted over or onto taller structures.

Work space dimensions can also factor in to the crane type decision. Wider areas will require a longer beam span. A longer span is much more easily achieved with a top-running configuration, since the columns, corbels or uprights will give added support to the elongated beam. However, for extra wide spans a double box girder design would be a much more economical choice.

Under Running Bridge Cranes

Under-running crane systems are typically constructed along the physical building structure. They can literally be hung from the ceiling. This can be very advantageous to facilities that require a lifting system but has limited to no floor space available for added structures, like columns, that a top running bridge crane requires. In these instances an under-running crane is ideal as only the building’s ceiling structure is required to support the crane.

However, one thing to consider when taking this approach is that the actual building must be constructed to withstand the extra burden that a crane and its load will require. Natural temperature fluctuations and added climate stresses such as seasonal snow and wind can sometimes cause structures to move and twist. This is a common, normal occurrence in steel structures, however it can be a detriment to any attached overhead crane systems. The misalignment can cause crane beams to move and end-trucks to jam, which could become costly to repair.

Under-running bridge crane systems are more commonly utilized in process environments. Facilities that require a load to be lifted from place to place along an assembly line would benefit more from an under-running configuration for a few important reasons. First, the absence of columns keeps the floor area open for actual assembly processes. Second, an under running configuration allows for the addition of interlocking mechanisms and switches. Process environments can benefit by connecting multiple under-running cranes via switches, either in a straight line or at an angle, allowing the trolley to move from one crane to the next and further down the assembly line, even changing direction. Thirdly, without the obstruction of support columns, this can allow room for multiple under-running cranes to be utilized in the same area.

Finally, under-running cranes typically come with a smaller price tag. Without the addition of extra columns, corbels or any type of supporting structure, an under-running crane can eliminate these supplementary costs.

Which is better?

Choosing the best configuration for an overhead crane depends on the needs of the customer and the facility. Many factors play a part towards the choice between top-running and under-running, such as head space, lifting capacities, work environment, span, weight, and even weather.

Contact the experts at Kristian Electric to make the decision process simple.