Can you guess what Bruce Springsteen did for work before he became one of the world’s most successful recording artists ever? Before he was dubbed “The Boss” and drove us down Thunder Road? Before he was Born to Run and reminisced about his Glory Days?

Well, nothing.

That’s right! Besides a few odd jobs mowing lawns as a kid, Springsteen has never been employed or held down a job. Since the release of his debut album, “Greetings from Ashbury Park” in 1973, Bruce Springsteen has mastered his craft of writing, recording, and performing his socially aware, poetically diplomatic, and nostalgic storytelling brand of rock n’ roll, and become one of the most acclaimed singer/songwriters of all time.

Since 1974, he has embarked on 17 headlining tours, 2 co-headlining tours as well as a concert residency on Broadway. Each tour ran between 1 – 2.5 years in duration with an average of 117 shows played each circuit. His live shows have become legendary for their energy and length, some lasting more than 4 hours!

For the past 5 decades, Bruce Springsteen has devoted his working life to rock and roll, always striving to maintain the top talent, production, and quality equipment for his tours.

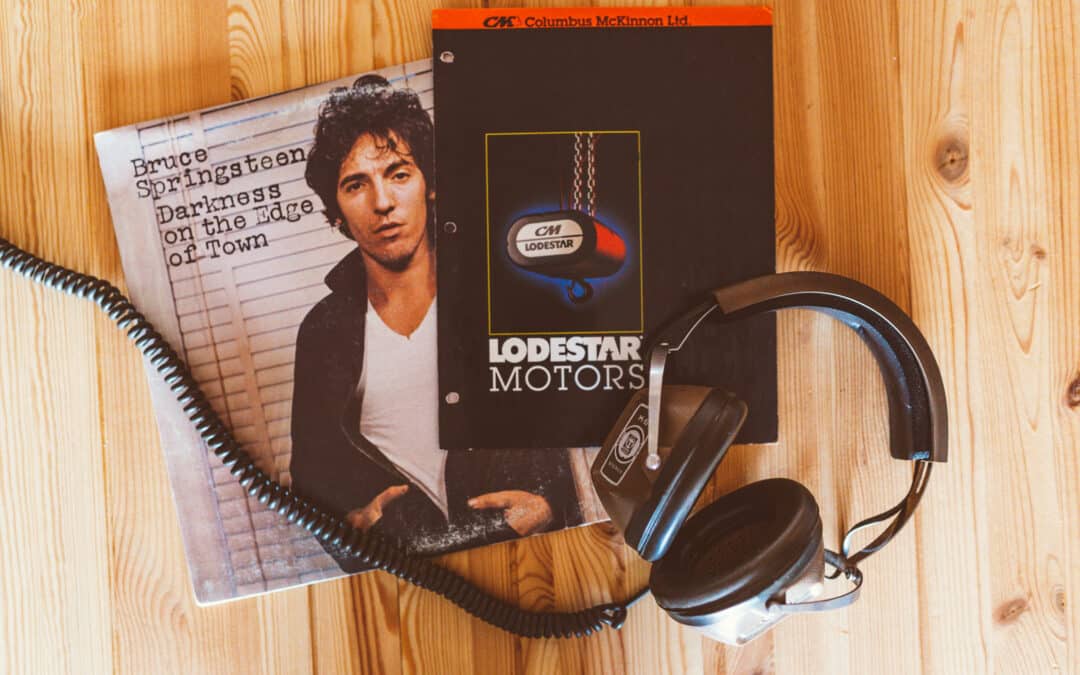

One such piece of equipment that has been a mainstay for the rigging crews at Springsteen concerts is the Lodestar Classic entertainment hoist from Columbus McKinnon. Introduced in 1955 the Lodestar has become an icon in the entertainment rigging industry known for its performance and reliability in the most demanding and challenging applications. During Springsteen’s 2012-13 Wrecking Ball tour, nine 2-ton and twenty-five 1-ton Lodestar hoists were depended upon to keep the 26-country tour running smoothly.

SPECIFICATIONS

Capacities: 1/8 to 2 tons (Metric Rated) Lift: 60 ft. standard (other lifts available) Speeds: 5 to 100 F.P.M. at 60 Hz. Voltages: 1-phase and 3-phase available

WATERPROOF FEATURES

Composite cord grips prevent water from entering the motor body at the pendant and power cord points of entry while continuous Gaskets create a waterproof seal between gearbox assembly and back frame and motor covers. O-Rings on Lift Wheel Bearing prevent water from entering the body through the lift wheel opening.

LOW VOLTAGE CONTROL

110 volt for long cable runs without voltage drop. 24 and 48 volt optional. Single-phase and three-phase also available.

IP66 RATING OF 66

An Ingress Protection (IP) Rating of 66 indicates that the Lodestar Classic offers protection from dust and high-pressure water – making this unit ideal for use in outdoor environments.

LONG SERVICE LIFE

Standard AC brake is designed for a long service life. Lifetime grease-lubricated gear box ensures better wear and smooth operation. Heavy-duty-rated motors. Standard external chain guide helps extend chain life

OVERLOAD & OVER-TRAVEL PROTECTION

Overload protector helps prevent lifting of dangerous overloads. Adjustable limit switch prevents load from over-travel in both up and down directions.

LIGHTWEIGHT, CAST-ALUMINUM HOUSING

Durable and strong cast-aluminum housing is black powder-coated for low visibility.

DUTY CYCLE

H-4 duty rated for heavy-duty applications. 2M+ FEM class. 50% duty cycle or 300 on/off per hour.

ADDITIONAL INFORMATION

Metric Ready. Road ready, easy to stow and travel. Lifetime warranty.

Springsteen isn’t the only one “Born in the USA”. Headquartered in Buffalo, New York, and with operation and production facilities in Tennessee, Virginia, North Carolina, and Ohio, Columbus McKinnon is proud to supply American-made, quality-craftsmanship hoists to the entertainment industry.

It’s distinct design, quieter operation and low maintenance have made the Lodestar Classic the boss of all entertainment hoists.

Click here to learn more about entertainment hoists and rigging.