This content reflects a period in Kristian Electric’s history when we were an authorized Demag dealer and warranty depot. Although that partnership ended in October 2025, our expertise didn’t — we continue to service Demag cranes, source parts, and support customers across Canada.

Work Smarter, Not Harder: Implementing Castellated Beams in Crane System Design

This past fall, Saskatoon carbon fiber composites manufacturer SED Research Inc. (SRI), a Calian subsidiary, commissioned Kristian to increase their shop productivity with the design and installation of three new overhead cranes. The cranes were needed by SRI to construct their line of 10M composite carbon fiber antennas for the satellite ground systems industry.

Their custom order included two Demag column-mounted jib cranes, 1 ton each, and a 5 ton Demag top running single girder bridge crane. These overhead cranes were chosen to assist SRI in their day to day production processes of manufacturing their sophisticated, state-of-the-art satellite earth station antennas. SRI provides composite carbon fiber reflectors to Calian SED, a global solution provider of advanced communication systems for over 50 years.

Both jib cranes were selected from a standard Demag construction, ensuring a straightforward and uncomplicated installation consistent with Demag’s quality design. However, the 5 ton bridge crane offered up a few challenges for the Kristian design and production team.

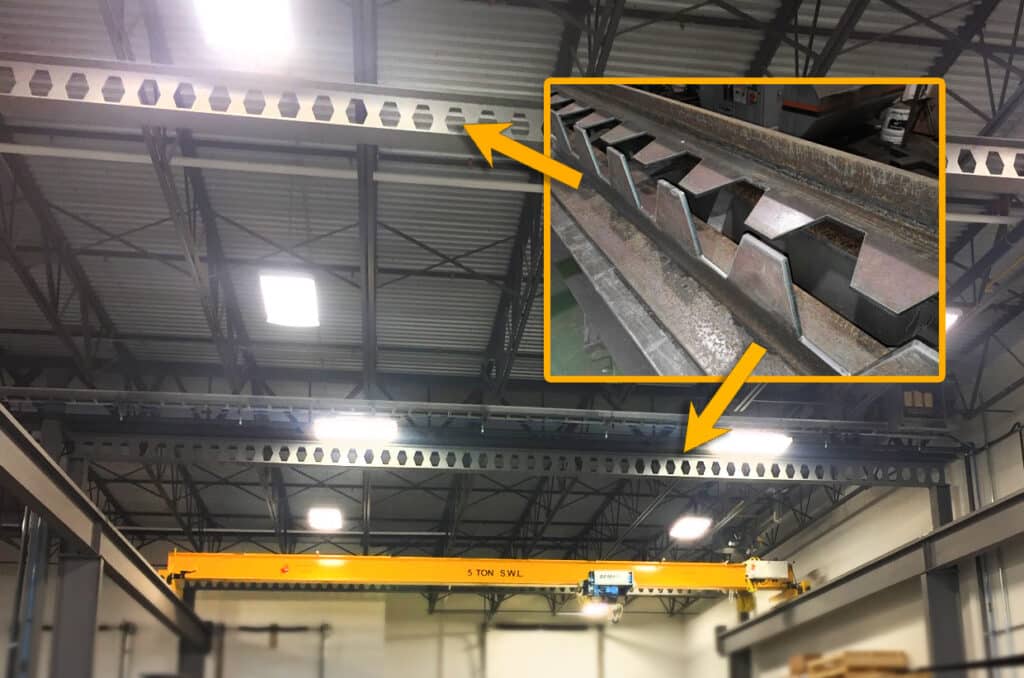

This is where our Kristian design and production team found an innovative solution to keep costs down without sacrificing SRI’s design specifications. Ernie Dajavs, Project Coordinator, proposed a plan to design and construct our own castellated beams to save time.

A castellated beam is made by cutting an I-beam down its longitude in a repeating, tooth-like pattern. Once the beam is separated into two parts, it is welded back together on an offset with the cut patterns mirroring each other; creating identical slots along the beam. The finished castellated construction allows for an increase in beam height without an increase in weight.

Kristian outsourced a local Edmonton company to have the beams professionally cut with their CNC equipment. When the freshly cut steel was returned to our Edmonton manufacturing shop, our fabrication department went to work welding the plasma-cut pieces back together in the castellated pattern.

Prior to being cut, the original beam measured 10” high, but once reconstructed the beam measured more than 15” without the standard additional weight.

“It is an estimated 30% lighter,” says Ernie Dajavs. “A truss beam would have taken us two to three days each just to manufacture, while the castellated-style only took about 6 hours each.”

Although the SRI project marked the first time Kristian has utilized this design in a crane system, it won’t be our last.

“It is an old-fashioned technique and you don’t see it used for cranes much anymore.” says Dajavs. “A beam’s strength comes from its depth (height), and by taking weight out and making it taller, it actually ends up making it stronger. It’s a neat way of doing it.”